The particulate matters(PMs) contained in vehicle exhaust emissions is known as one of the toxic chemical substances for human health and is restricted by the exhaust emissions regulations in adding to hydrocarbon(HC), carbon monoxide(CO) and nitrogen oxides(NOx) components.

The ultra fine PMs (< 0.1um in daiameter) from diesel vehicles seems especially to be affected to the human health and the emissions regulations have recently been strengthened in many countries, as a result that the number concentration and total mass PMs in exhaust emissions have greatly been reduced so that applying the conventional filter paper method for weighing the mass particle matters will be expected to close its limitations.

By this reason, a new method to count the particle number concentration was being studied globally around Europe in adding to the conventional filter paper method and it will be expected to introduce in September 2011 for Euro 5b.

Therefore, an instrument is required to measure particle numbers in diesel exhaust emissions - known as PN.

A new instrument for counting the particle numbers in diesel exhaust emissions is regulated by PMP standard (Particle Measurement Program) in EU and the system should be configured fully compliant with this standard.

Products

The system consists of a single-count-mode condensation particle counter to count particle numbers (PNC), and volatile particle remover(VPR).

The VPR includes exhaust gas diluters which can supply diluted exhaust gas to the a PNC and volatile particle remover.

The sample aerosol taken from CVS tunnel goes into the VPR to remove volatile particles and the particle numbers are counted by the PNC.

The VPR consists of a couple of diluters and heater.

The primary diluter can dilute sample aerosol more than 10 times with the dried air and the diluted sample aerosol goes into the evaporation tube(ET) to remove volatile particles, then finally the heated aerosol is rapidly diluted in the secondary diluter to prevent re-condensation of volatile particles.

Features

- Compliant with EURO 5b and EURO 6

- Accurate flow control

- High ratio diluter : 100, 200, 500 and 1000 times

- Easy operation with user friendly interface

1. User friendly screen design

2. Capable of multiple tasks on the same PC

3. Full monitoring and saving the major parameters(flow rate, pressure and temperature)

4. Useful graph creator with data selecting window

5. Automatic logging system for alarm

6. start logging with external trigger

Simple mode operation screen

Full mode operation screen

- Equipped with daily checking functions

1. Check the contaminated particles in the VPR : every test

2. Check the temperature in the evaporation tube : every test

3. Check the temperature in the primary diluter : every test

4. Function check for the PNC(CPC) : every day

5. Flow check of the PNC(CPC) : every month

- Easy maintenance

1. Free access from rear side to the standard maintenance parts integrated on the inner rear panel.

2. Easy maintenance for the line filter

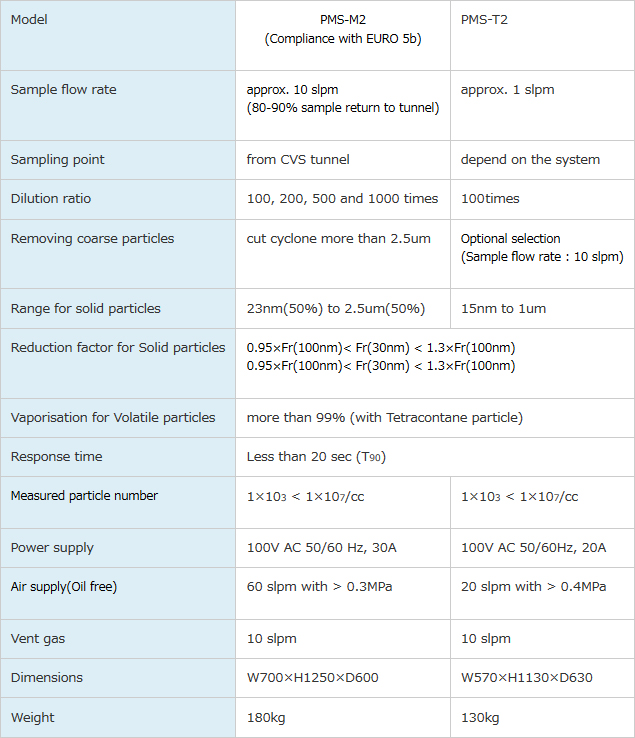

Specifications

Option models

Available the model to sample from dilution tunnel or directly from tail pipe out (PMS-T2).

- Heated sample line with diluter

- Sampling accessory for dilution tunnel

- Cyclone to remove coarse particles

- Accessory for direct exhaust sampling

Calibration

- Calibration of PNC(CPC)

It is required to make the calibration to the PNC(CPC) compared with the standard aerosol electrometer or condensation particle counter which are calibrated with the standard aerosol electrometer.

- Detection efficiency

Calibration interval should be within a year. - Calibration interval

1. Calibration of the PNC(CPC)

Linearity : every year

Detection efficiency : every year

2. Calibration of the VPR

Reduction factor for Solid particles : every year

Vaporisation for volatile particles : every year

3. Dairy checking list

-1) Residual particles in the VPR : every test

-2) Evaporation tube temperature : every test

-3) Primary diluter temperature : every test

-4) Function check of the PNC (CPC) : every day

-5) Flow check of the PNC (CPC) : every month

EU Regulations

A new EU regulations of particle numbers (6*1011/km) for Euro 5b on diesel engine vehicles will be started from September 2011 in addition to the conventional mass PMs(5.0mg/km to 4.5mg/km).

A new category vehicle (6*1011/km) with gasoline direct injection engine will be included in this regulation in a period of transition for Euro 6 from 2014.

New proposals are also being suggested to legislate mass NOx and THC+NOx in a period of transition for Euro 6 (depend on the category of vehicles)

Applications

- Approval tests for PN from the vehicles export to the EU countries

- Several kind of DPF tests

- GDI engines research

FAQ

Is it possible to take sample from tail pipe with PMS-M2?

It is not possible because PMS-M2 is designed only for taking sample from CVS tunnel. It may be possible to take sample from tail pipe with another model of PMS-T2.

Is it required to make some additional constructions during the installation?

Only require the power supply, air supply with 0.3MPa and exhaust ducts are required.