It is necessary to measure Air Fuel Ratio (AFR) to reduce exhaust emissions and to save fuel economy. Sokken provide the two types of Air Fuel Ratio Meter of a high precision model and a portable one.

| MCS-3 Brochure | PDF(593.3 KB) |

|---|---|

| Air Fuel Ration Meter PLR-7 Leaflet | PDF(198.4 KB) |

Products

Line-up

|

High precision Air Fuel Ratio Meter MCS-3a is capable to measure high precision AFR without to be influenced by the coexistence unburned gases such as HCs and CO in rich combustion exhaust gas. The MCS system mainly consists of metering capillaries for sample gas and air, catalyst and a Zirconia Oxygen sensor. The Oxygen concentration is measured by Zirconia sensor after the unburnt gases were fully oxidized over catalyst. The AFR is calculated by the Oxygen concentration and the dilution rate. |

|

Features

|

|

Portable Air Fuel Ratio Meter PLR-7 is the small and light weight air fuel ratio meter by using multiple layered UEGO sensors. It is simple to use by installing the UEGO sensor to exhaust pipe. |

|

Features

|

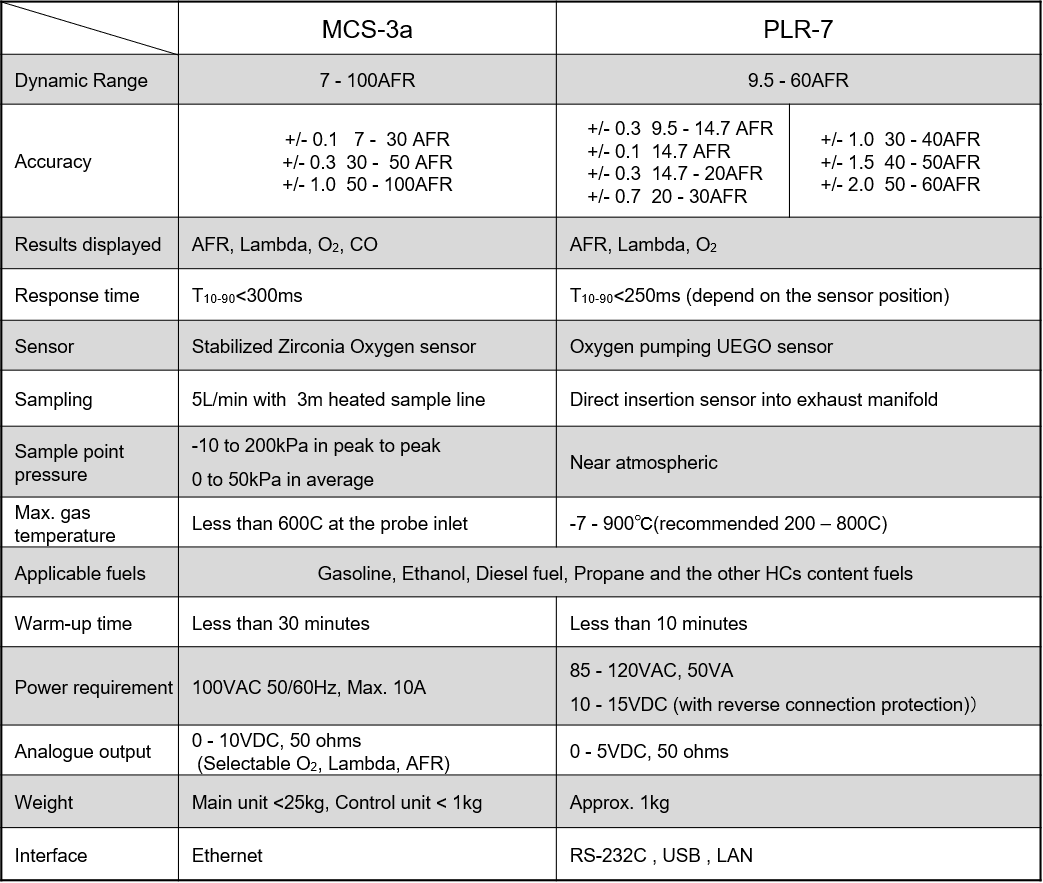

Specifications

Relevant products

Fast Engine Exhaust Gas Analyzers

Applications

FAQ

Can it also be used for hydrogen engine performance tests?

Our air-fuel ratio meter is also used to verify the performance of hydrogen engines. Please contact us for more information.

Are both instruments for MCS-3a and PLR-7 applicable for Alcohols fuel?

Yes, of course they are by changing the H/C and O/C ratios.

How often the service interval for catalyst?

The catalyst shall be replaced every 200 hours in the integration time.

Is it possible to get another new UEGO sensor?

Yes, it is.

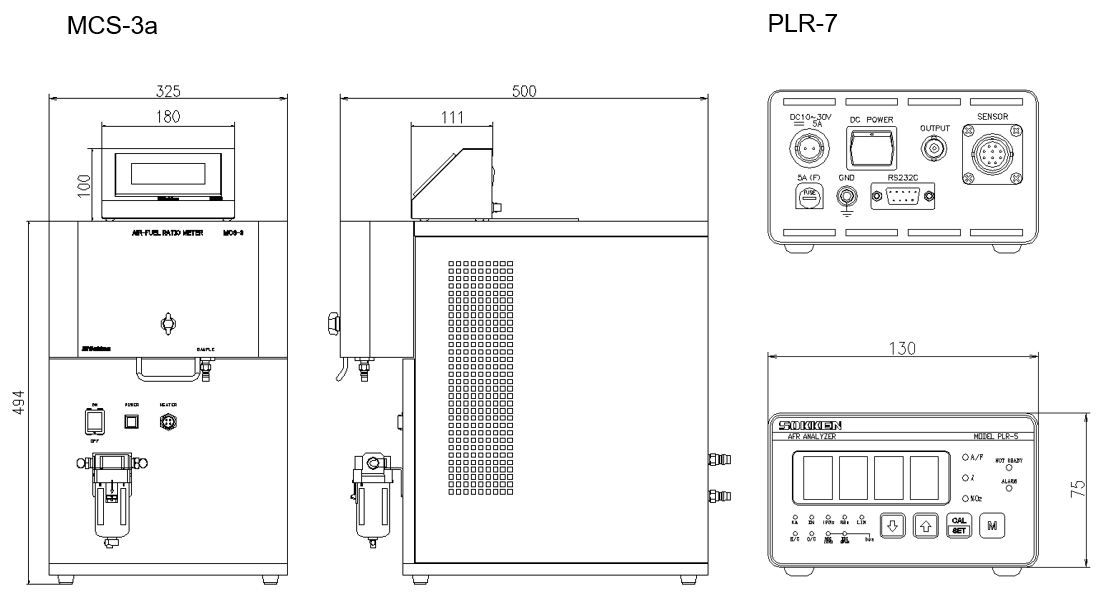

External view

Priciple

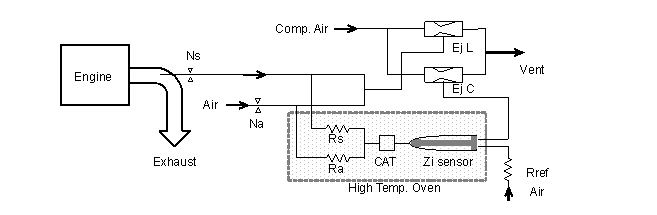

High precision Air Fuel Ratio Meter MCS-3a

The system is configured with a pair of metering capillaries to dilute the sample gas with air, an oxidation catalyst and also a solid stabilized Zirconia sensor.

The oxygen concentration is measured by Zirconia sensor after the oxidation catalyst without diluting the sample gas with air in lean region since the oxygen molecule is still remaining in the exhaust sample gas. However there is no oxygen molecule in the sample gas in rich region, so it is necessary to dilute the sample gas with known amount of air and oxidize the unburnt gas such as HCs and CO to measure the oxygen concentration after the oxidation catalyst.

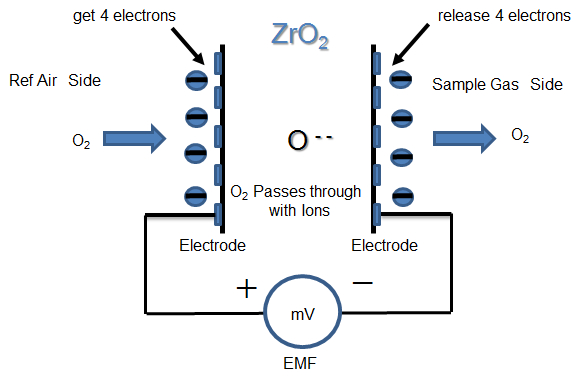

A Platinum coated Zirconia ceramic thin layer generates ElectroMotive Force (EMF) at the both sides of the layer if there is an Oxygen concentration difference under very high temperature condition.

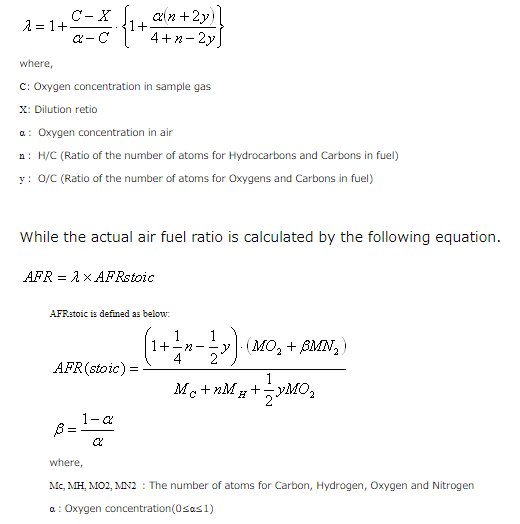

It is necessary to control the flow rate for sample gas and reference air for each side and the temperature of the thin layer precisely. The Lambda is calculated by the equation as follows based on the unique flow schematic:

It is necessary to control the flow rate for sample gas and reference air for each side and the temperature of the thin layer precisely. The Lambda is calculated by the equation as follows based on the unique flow schematic:

Portable Air Fuel Ratio Meter PLR-7

PLR-7 uses the multi layered thin Zirconia ceramic sensor for On-board type of air fuel ratio control sensor called UEGO sensor.

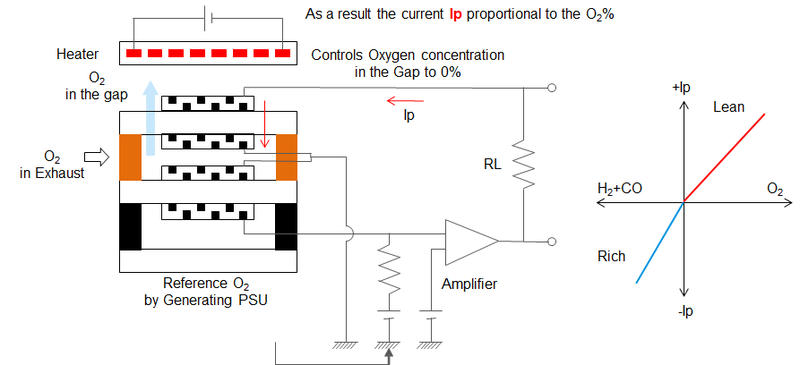

Principle in lean region

For lean region in Lambda>1, the sensor controls the oxygen concentration in the upper cavity to zero by pumping the oxygen molecule to control the current Ip in the circuit as shown the red arrow in the diagram. The Lambda and AFR are calculated from the Ip as shown in the graph.

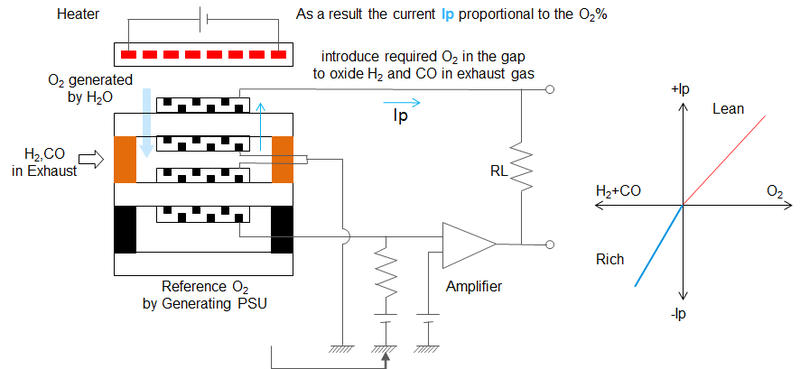

Principle in rich region

For rich region in Lambda<1, the sensor controls the upper cavity to oxidize H2 and CO perfectly by pumping the required oxygen molecule to control the current Ip in the circuit as shown the blue arrow in the diagram. The Lambda and AFR are calculated from the Ip as shown in the graph.

Since the lower cavity as a reference side of the electrode, the oxygen concentration in the lower cavity keeps always constant to control the reference PSU current as shown in the diagram.